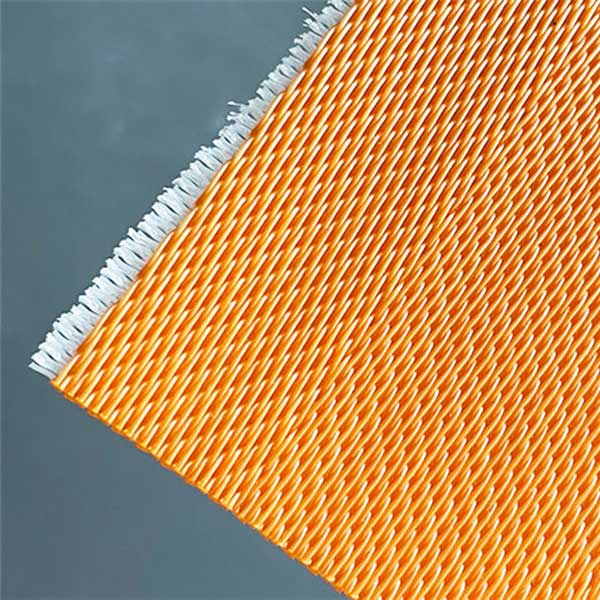

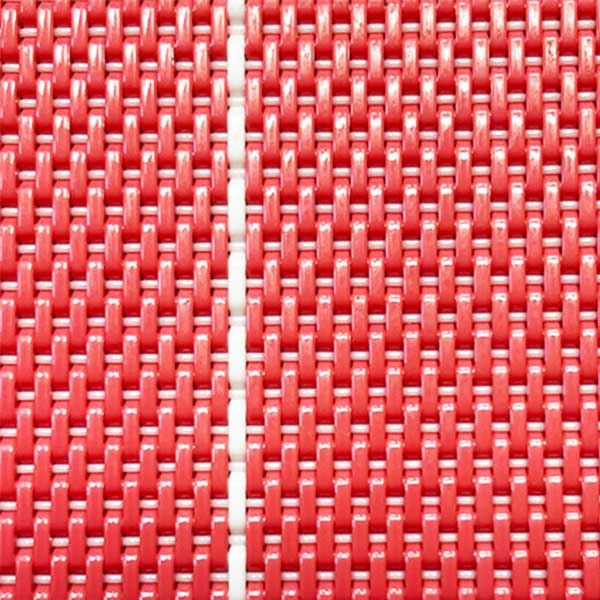

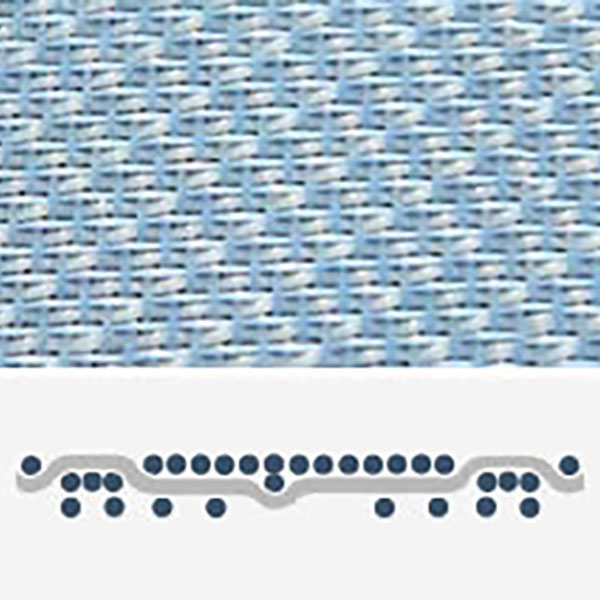

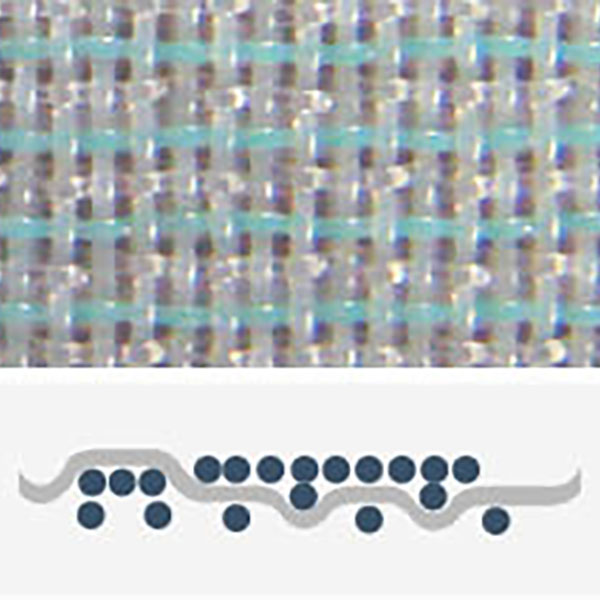

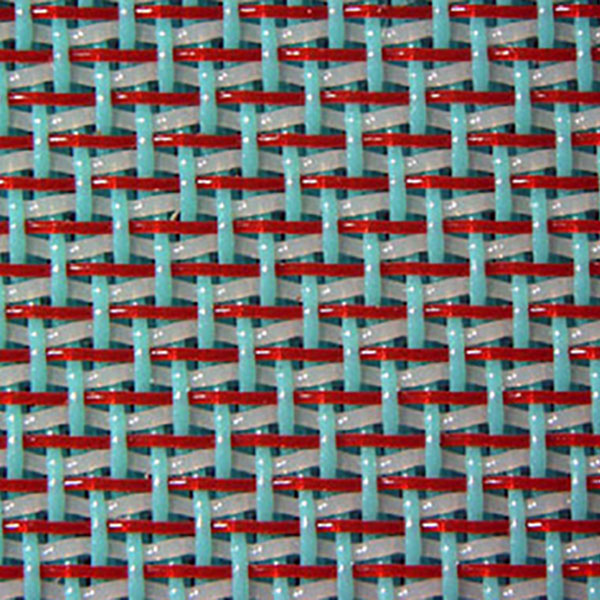

2.5 Layer Forming Fabric Paper Forming Wire(PMC)

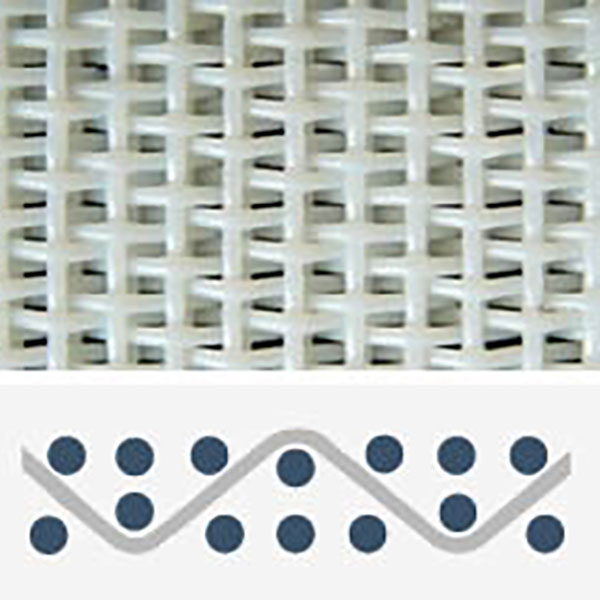

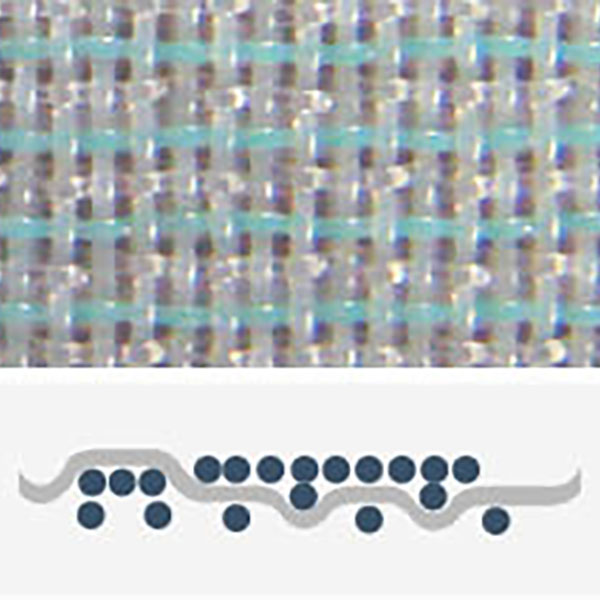

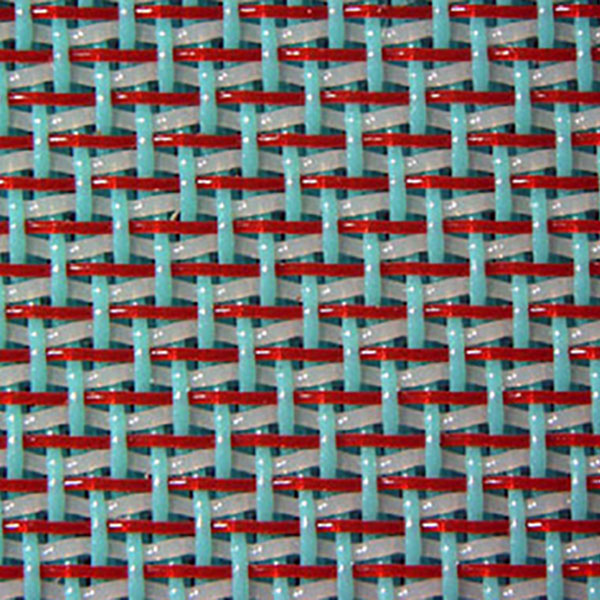

The 2.5-layer forming fabric is designed to allow for a higher degree of fiber retention without losing its dewatering properties. This design has a higher fiber support index than a double-layer filament design.

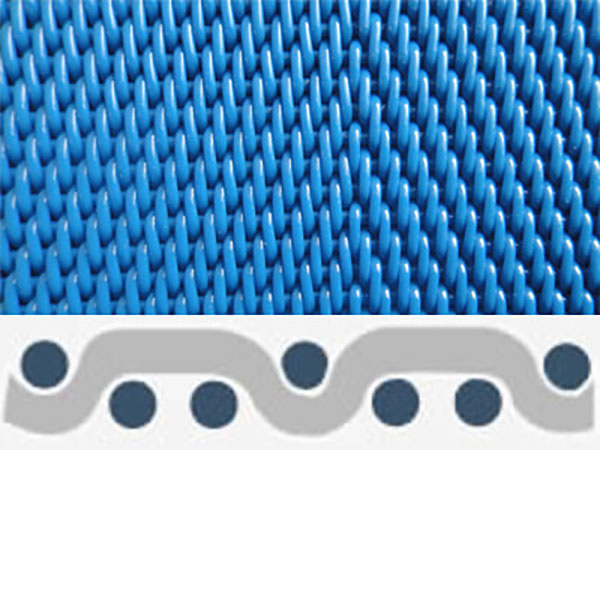

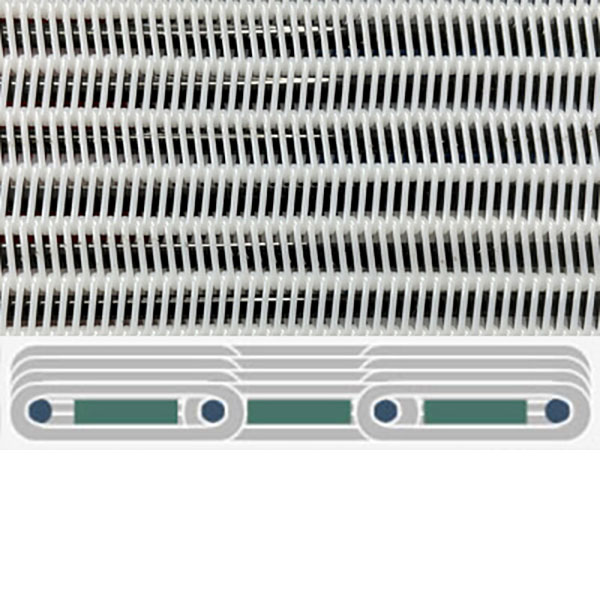

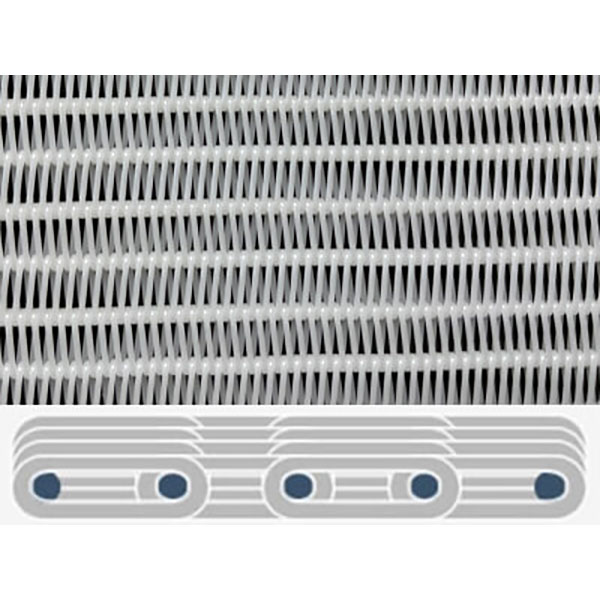

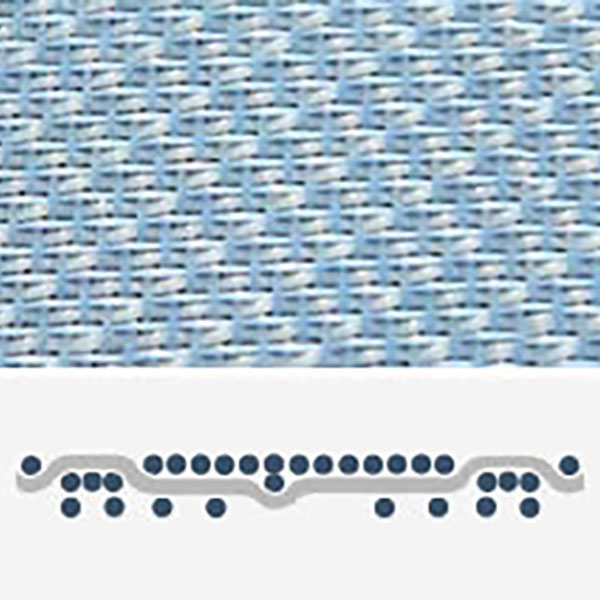

- Double MD yarn lock on machine side, can withstand high MD load and resist CD wrinkling.

- Increased machine side weft diameter and long CD crimp provide longer service life.

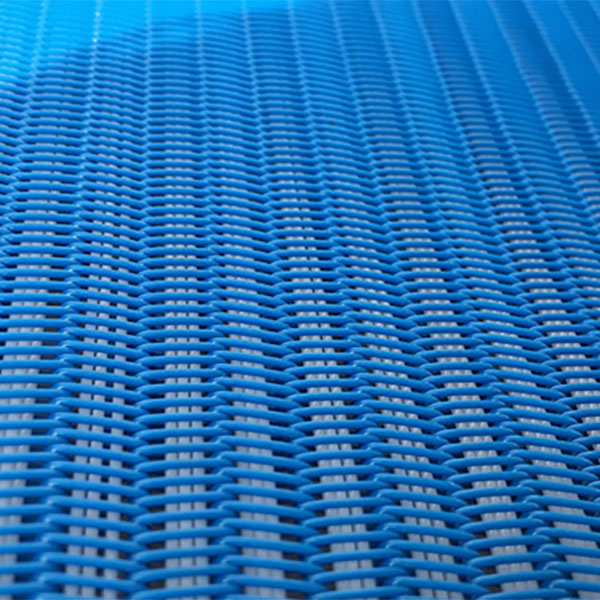

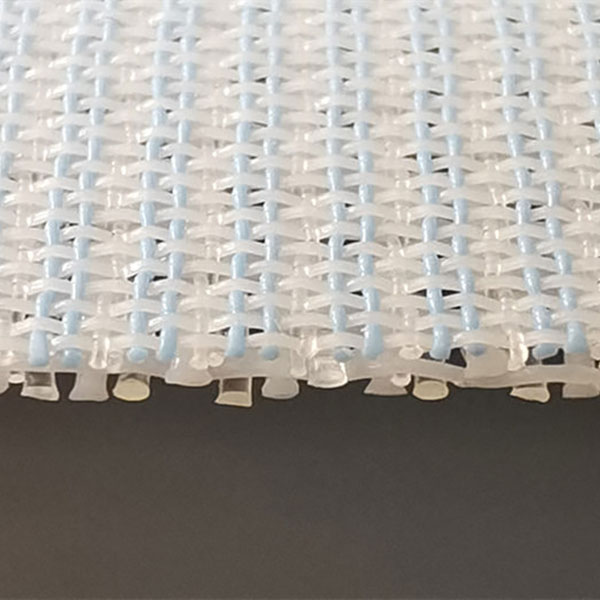

- No traces of fabric and easy to clean;

- Very good stability and wear resistance;

- Good paper feeding and holding power

2.5 Layer Forming Fabric Description

The 2.5-layer forming fabric is a double-layer fabric that supports Shute. It adopts a double-layer design and adds extra Shute yarns between regular transverse yarns to increase paper support and improve paper properties. During the weaving process, the weft density on the side of the piece is increased, the number of weft yarns on the machine side is reduced, and the drainage capacity is enhanced. This design maintains high fiber retention while improving dewatering performance and improving fiber support index by adding top transverse braiding lines

2.5 Layer Synthetic Forming Mesh Data Sheet

| Model | Thread Diameter(mm) | Density(No.s/cm) | Air Permeability | ||

| Warp | Weft (top/bottom) | Warp | Weft | (m³/m²h) | |

| 2B3316 | 0.28 | 0.20,0.27/0.40,0.40 | 37~38 | 40~41 | 6000 |

| 2B3316-1 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 37~38 | 6000 |

| 2B3316-2 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 31~32 | 8000 |

| 2B5008 | 0.17 | 0.13,0.18/0.32,0.32 | 55~56 | 48~49 | 6500 |

| 2B5216 | 0.17 | 0.17,0.22/0.27,0.27 | 57.5~58.5 | 50~51 | 5300 |

| 2B5216-1 | 0.17 | 0.19,0.22/0.35,0.35 | 57.5~58.5 | 43.5~44.5 | 6200 |

| 2B5408 | 0.17 | 0.13,0.20/0.35,0.35 | 59~60 | 43~44 | 6300 |

| 2B5416 | 0.17 | 0.13,0.20/0.35,0.35 | 59.5~60.5 | 42~43 | 6000 |

| 2B5608 | 0.17 | 0.13,0.18/0.22,0.22 | 61~62 | 52~53 | 5700 |

| 2B5608-1 | 0.17 | 0.13,0.20/0.25,0.25 | 60~61 | 54~55 | 5600 |

| 2B5608-2 | 0.17 | 0.13,0.20/0.32,0.32 | 60~61 | 48~49 | 6000 |

| 2B5608-3 | 0.17 | 0.13,0.20/0.35,0.35 | 60~61 | 47~48 | 5600 |

| 2B5608-4 | 0.17 | 0.13,0.20/0.32,0.32 | 61.5~62.5 | 55.5~56.5 | 6900 |

| 2B5608-5 | 0.18 | 0.13,0.18/0.22,0.22 | 62~63 | 53~54 | 6800 |

| 2B5608-6 | 0.18 | 0.13,0.20/0.25,0.25 | 61~62 | 61~62 | 5940 |

| 2B5608-7 | 0.15 | 0.13,0.18/0.25,0.25 | 62~63 | 53~54 | 6600 |

| 2B5608-8 | 0.15 | 0.13,0.18/0.32,0.32 | 61~62 | 56~57 | 6400 |

| 2B5608-9 | 0.17 | 0.13,0.18/0.35,0.35 | 61~62 | 51~52 | 6900 |

| 2B5608-10 | 0.17 | 0.13,0.22/0.35,0.35 | 61.5~62.5 | 48.5~49.5 | 5800 |

| 2B5808 | 0.17 | 0.13,0.18/0.22,0.22 | 63~64 | 53~54 | 6500 |

| 2B5808-1 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 54~55 | 5000 |

| 2B5808-2 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 51.5~52.5 | 5100 |

| 2B6208 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 56.5~57.5 | 5500 |

| 2B6208-1 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 54.5~55.5 | 6000 |

| 2B6208-2 | 0.17 | 0.13,0.18/0.23,0.23 | 63~64 | 51.5~52.5 | 5100 |

| 2B6216 | 0.17 | 0.13,0.18/0.23,0.23 | 68~69 | 61.5~62.5 | 5600 |

| 2B6216-1 | 0.17 | 0.13,0.20/0.25,0.25 | 68~69 | 64.5~65.5 | 6400 |

| 2B6216-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68~69 | 51.5~52.5 | 5400 |

| 2B6216-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 52.5~53.5 | 5500 |

| 2B6216-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 49.5~50.5 | 8000 |

| 2B6216-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 46.5~47.5 | 7000 |

| 2B6408 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 57~58 | 6200 |

| 2B6408-1 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 65~66 | 6500 |

Get free Quote of 2.5 Layer Forming Fabrics

Improve your papermaking with HEZER’s forming fabrics

2.5 Layer Forming Mesh Applications

The 2.5-layer forming fabric is suitable for the production of a variety of paper, such as printing paper, packaging paper, cardboard, etc. The paper machine speed range is 200-500 m/min, ensuring efficient and stable production.

Related Products

Related News

65 / 100 Powered by Rank Math SEO SEO Score Introduction: The Cutting Edge of Paper Production Technology At HezeRbelt, […]

61 / 100 Powered by Rank Math SEO SEO Score Introduction: The Value of Proper Maintenance At HezeRbelt, we know […]

61 / 100 Powered by Rank Math SEO SEO Score Introduction: The Importance of Choosing the Right Manufacturer At HezeRbelt, […]

61 / 100 Powered by Rank Math SEO SEO Score Table of Contents Understanding HEZER’s Papermaking Technology Core Benefits of […]

65 / 100 Powered by Rank Math SEO SEO Score In today’s highly competitive paper manufacturing industry, production efficiency and […]

64 / 100 Powered by Rank Math SEO SEO Score In the highly competitive paper production industry, choosing the right […]